For smart lighting systems, FERRTX components enable seamless dimming control (0-10V/PWM/DALI protocols) and color temperature adjustment through specialized inductor designs that maintain stability across 100%-1% dimming ranges. Our engineering team collaborates closely with lighting manufacturers to develop customized solutions addressing unique thermal management challenges in high-power LED arrays or compact form factors. The combination of high-temperature resistant alloys (operating range -40°C to +150°C) and vacuum impregnation processes extends component lifespan beyond industry averages, reducing maintenance intervals and total cost of ownership.

With 37 years of experience serving 500+ global clients, FERRTX has deployed solutions in over 2,300 lighting projects including streetlights, stadium illumination and architectural lighting systems. Our four automated production facilities (12,000㎡ total) leverage IATF 16949-certified processes to deliver components with <1% defect rates, supported by lifetime technical assistance for driver circuit optimization and EMI troubleshooting. By integrating FERRTX magnetic components, lighting manufacturers gain access to patented winding technologies and custom core materials that enhance efficacy while meeting ENERGY STAR and DesignLights Consortium performance benchmarks.

The attached company profile highlights our full-range capabilities from prototype development to mass production, including:

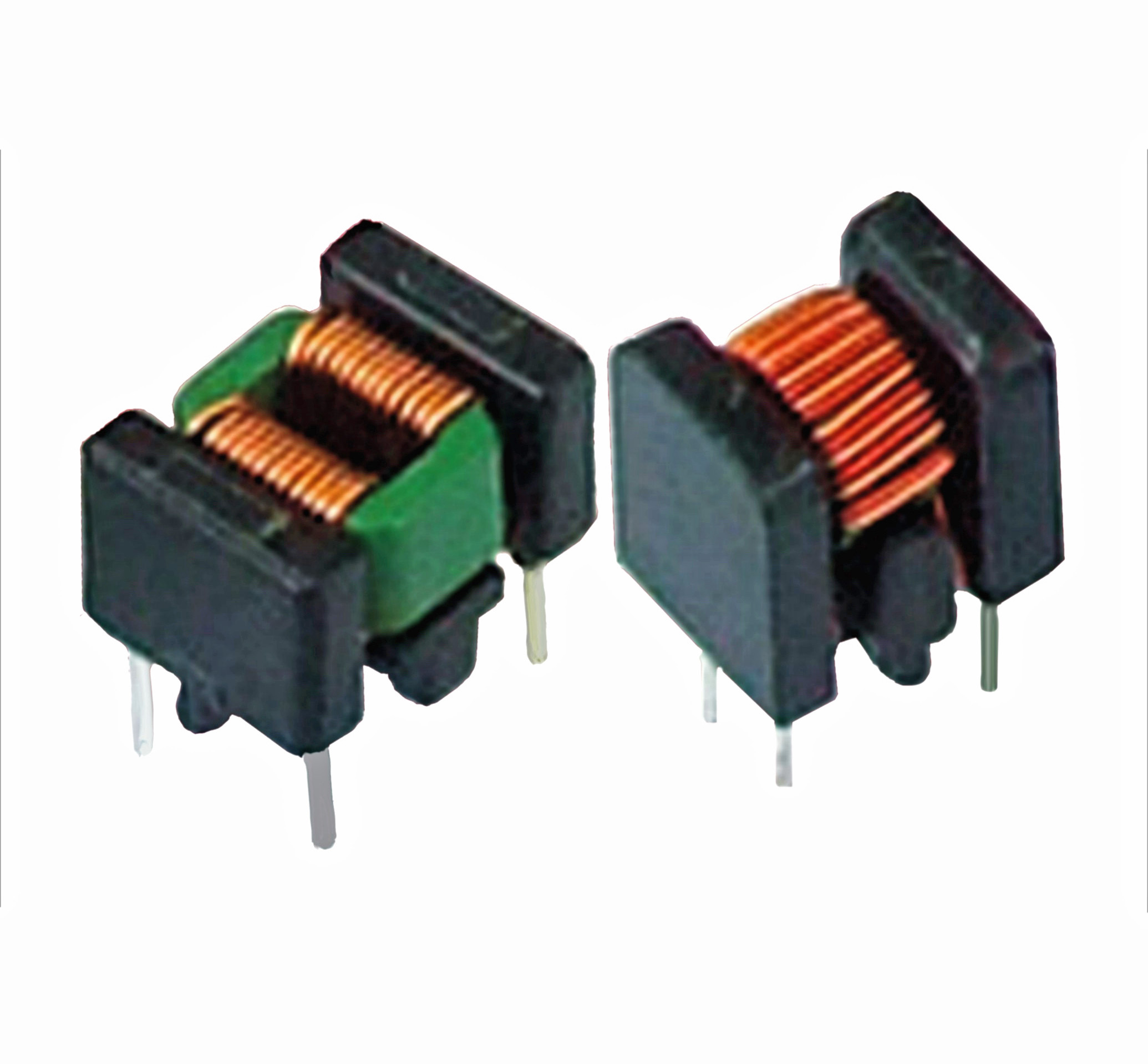

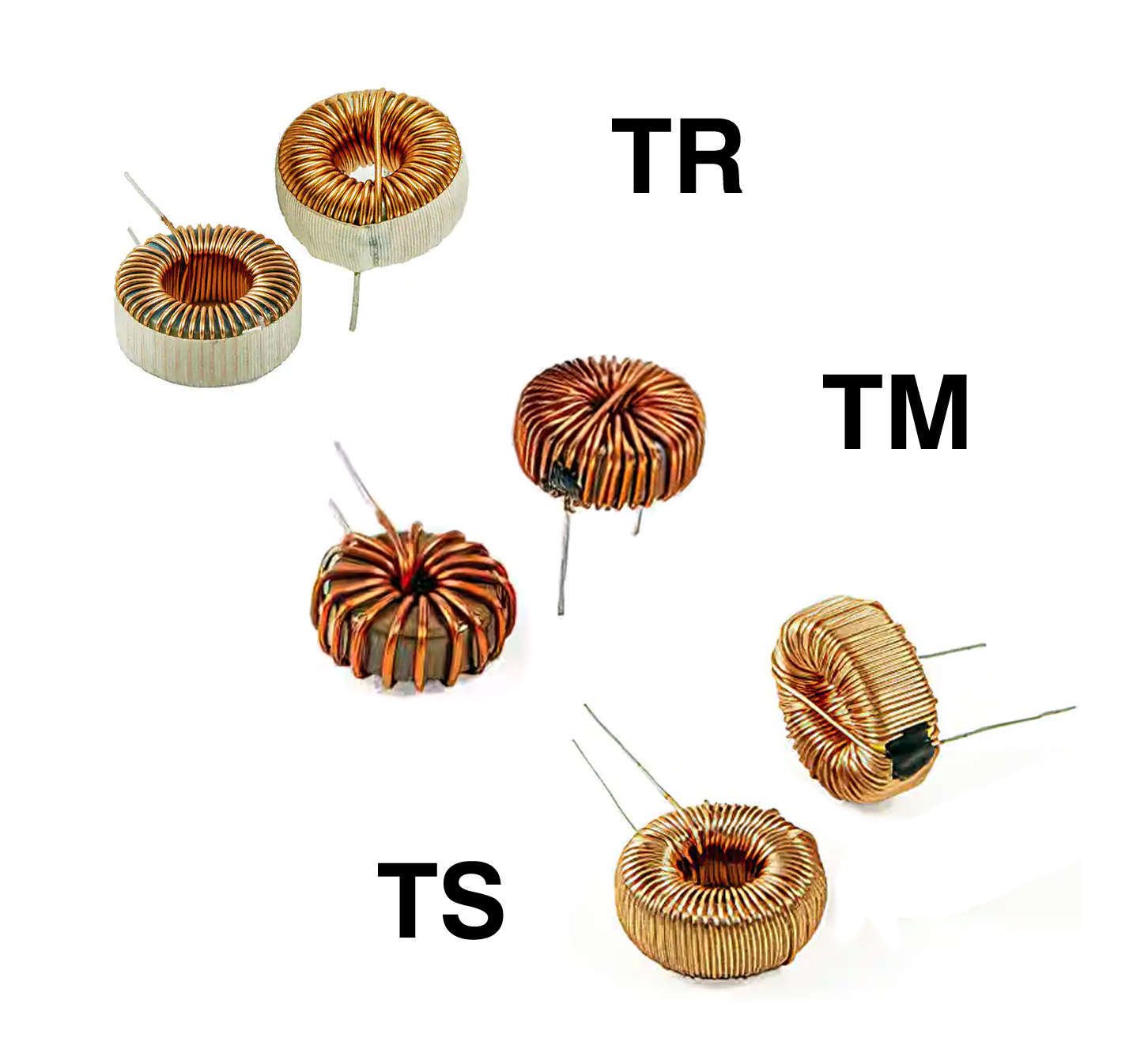

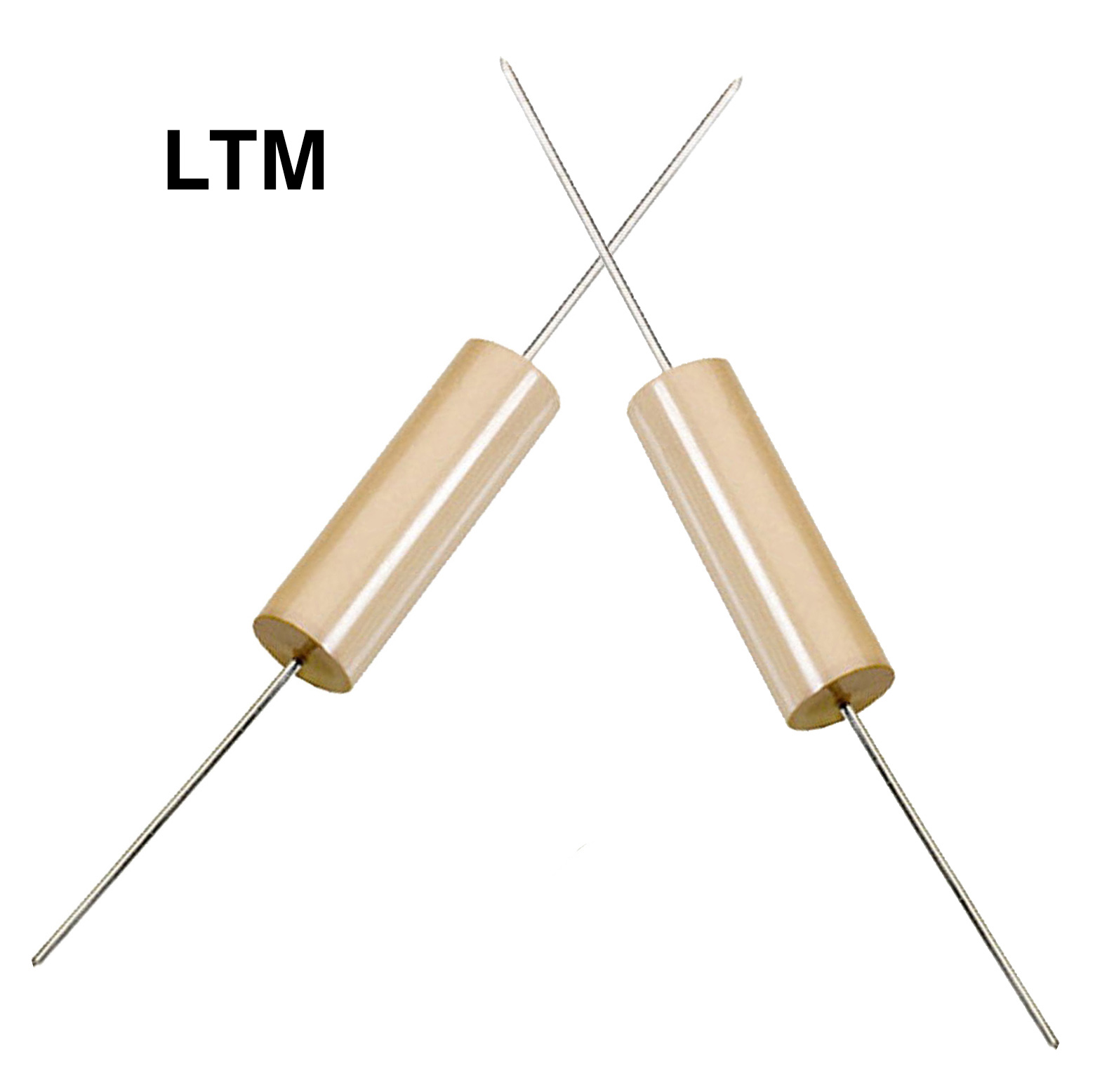

· Power inductors for constant current LED drivers

· Planar transformers for slim-profile luminaires

· EMC filters achieving >40dB noise suppression

· Current sensors with ±1% measurement accuracy

For project-specific requirements, our 150-member engineering team provides application analysis and magnetic solution customization within 72-hour response windows, backed by comprehensive simulation tools and an in-house EMI testing chamber.