Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Product Categories

As the search for more efficient power electronics continues, ultra-wide-bandgap semiconductors are emerging as a promising frontier. While silicon carbide (SiC) and gallium nitride (GaN) have driven considerable progress, diamond-based semiconductors offer even greater theoretical potential. This article explores the unique advantages and ongoing challenges of diamond semiconductors, reviews recent device developments, and highlights practical applications, with insights from industry experts including Patrick Le Fèvre.

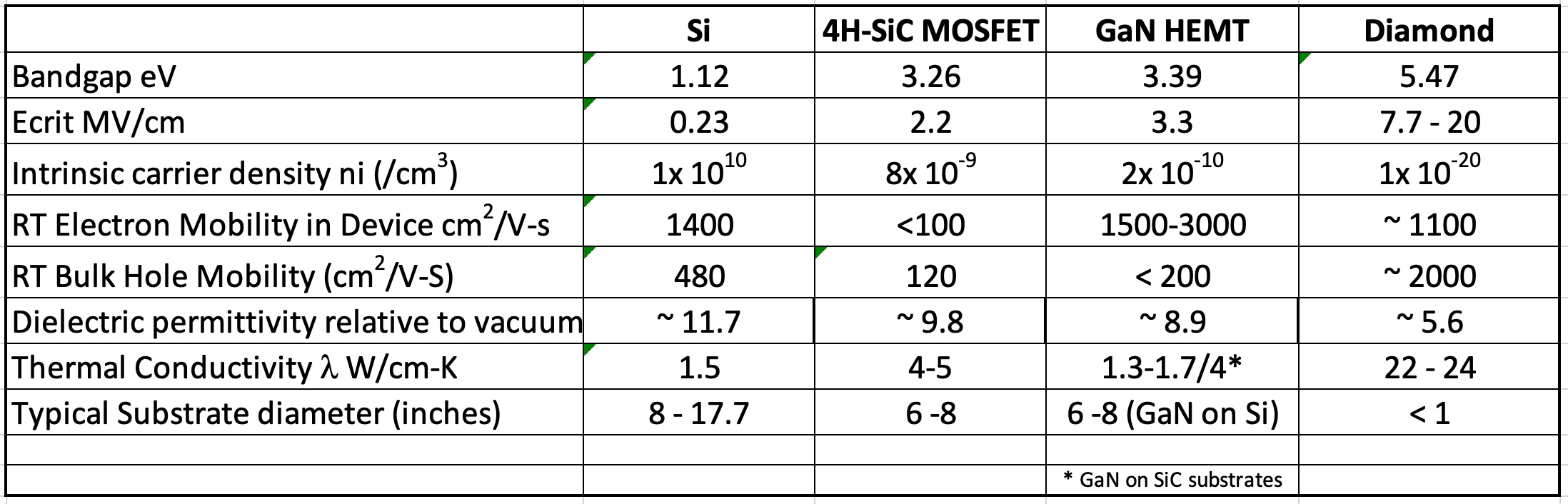

When comparing fundamental material properties—such as those of silicon, SiC, GaN, and diamond—diamond consistently stands out in several areas. Its wider bandgap contributes to a higher critical electric field and improved breakdown strength. Diamond also exhibits high bulk carrier mobility, which helps reduce conduction losses and support higher current density. Additionally, its low dielectric constant allows for reduced power loss and device miniaturization, especially in high-frequency applications.

Another standout feature is diamond’s exceptional thermal conductivity—the highest among all known materials. This property lowers thermal resistance, enabling higher power density for a given temperature increase and reducing thermomechanical stress. These benefits also make diamond a compelling choice as a thermal substrate material in high-power systems.

Diamond offers several other advantages not captured in standard property tables. For example, hydrogen-terminated surfaces facilitate local electron exchange into the valence band, leading to the formation of a two-dimensional hole gas (2DHG). This effect is valuable for creating high-mobility channels in transistor structures.

Diamond electronics are also inherently radiation-resistant, making them suitable for specialized environments such as nuclear facilities and space systems. In high-frequency applications, particularly in the sub-terahertz and terahertz ranges, diamond’s plasmonic response within the 2DHG and its high hole momentum relaxation time offer further performance benefits.

Wider adoption of diamond semiconductors has been limited by difficulties in producing large, high-quality substrates. The high-pressure high-temperature (HPHT) method can produce high-purity synthetic diamond crystals, but it is generally limited to small-diameter Type IIa substrates. Alternatively, chemical vapor deposition (CVD) offers a more economical path to larger substrates, typically up to 2–3 inches in diameter. Type Ib diamond, commonly used in electronics, still exhibits higher defect densities compared to established materials like SiC.

Homoepitaxial CVD growth builds on HPHT seed layers, while heteroepitaxial approaches use foreign substrates such as iridium-coated silicon or cubic SiC. The latter enables larger wafer sizes but often introduces higher defect levels and mechanical stress.

Doping is another significant hurdle. Although boron allows for p-type conductivity in diamond, achieving high dopant concentrations without degrading crystal quality remains difficult. Nitrogen and phosphorus have been explored for n-type doping, but their deep energy levels make effective n-type conduction hard to realize at room temperature.

Hydrogen termination offers another doping pathway via surface transfer, enabling 2DHG formation with a carrier mobility of around 300 cm²/(V·s). While this is lower than bulk diamond values, it remains stable across temperature variations.

In bulk-conduction diamond devices, increased temperature leads to higher net carrier concentrations, resulting in a negative temperature coefficient (NTC) of on-state resistance. This unusual trait reduces conduction loss at high temperatures, giving diamond an efficiency edge over SiC and GaN above 400–450 K. However, the NTC behavior complicates device paralleling due to the risk of current imbalance and thermal instability.

Recent experimental results highlight diamond’s potential:

A p-type lateral Schottky barrier diode reached a breakdown voltage of 4,612 V using an Al₂O₃ field plate.

Vertical 2DHG-based p-MOSFETs with Al₂O₃ gate dielectric achieved current conduction exceeding 1 A.

An enhancement-mode p-MOSFET was realized using UV ozone treatment to modify a hydrogen-terminated surface.

Theoretical analyses, such as one by Donato et al., suggest that a 1,700 V vertical diamond FET could be 10 times smaller and have three times lower power loss than comparable WBG devices under high-temperature, high-frequency operation.

As diamond devices advance, reliability under extreme conditions remains a critical area of study. New testing standards will likely be needed to evaluate long-term performance. Although diamond’s thermal properties may simplify heat sink design, integrating diamond components with other semiconductors—such as n-type WBG devices or silicon-based drivers—demands careful thermal and packaging design.

The 2011 Fukushima Daiichi nuclear accident highlighted the need for electronics capable of operating under extreme radiation and temperature. In response, the Japanese startup Ookuma Diamond Device—founded in 2022 following collaborative R&D involving several national research institutions—has developed a diamond-MOSFET-based differential amplifier that functions at 300°C. With reported lab yields reaching 90%, this example illustrates diamond’s potential in real-world harsh-environment applications.

Let's get in touch.

About Us

Related Products List

Contact Us

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.