Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: FERRITES

Transportation: Land,Ocean,Air,Express

Place of Origin: China

Supply Ability: 2~8weeks

Certificate: RoHS/ISO/UL/CE/IATF16949/CNAS

Port: Xi'an,Shanghai

Payment Type: L/C,T/T

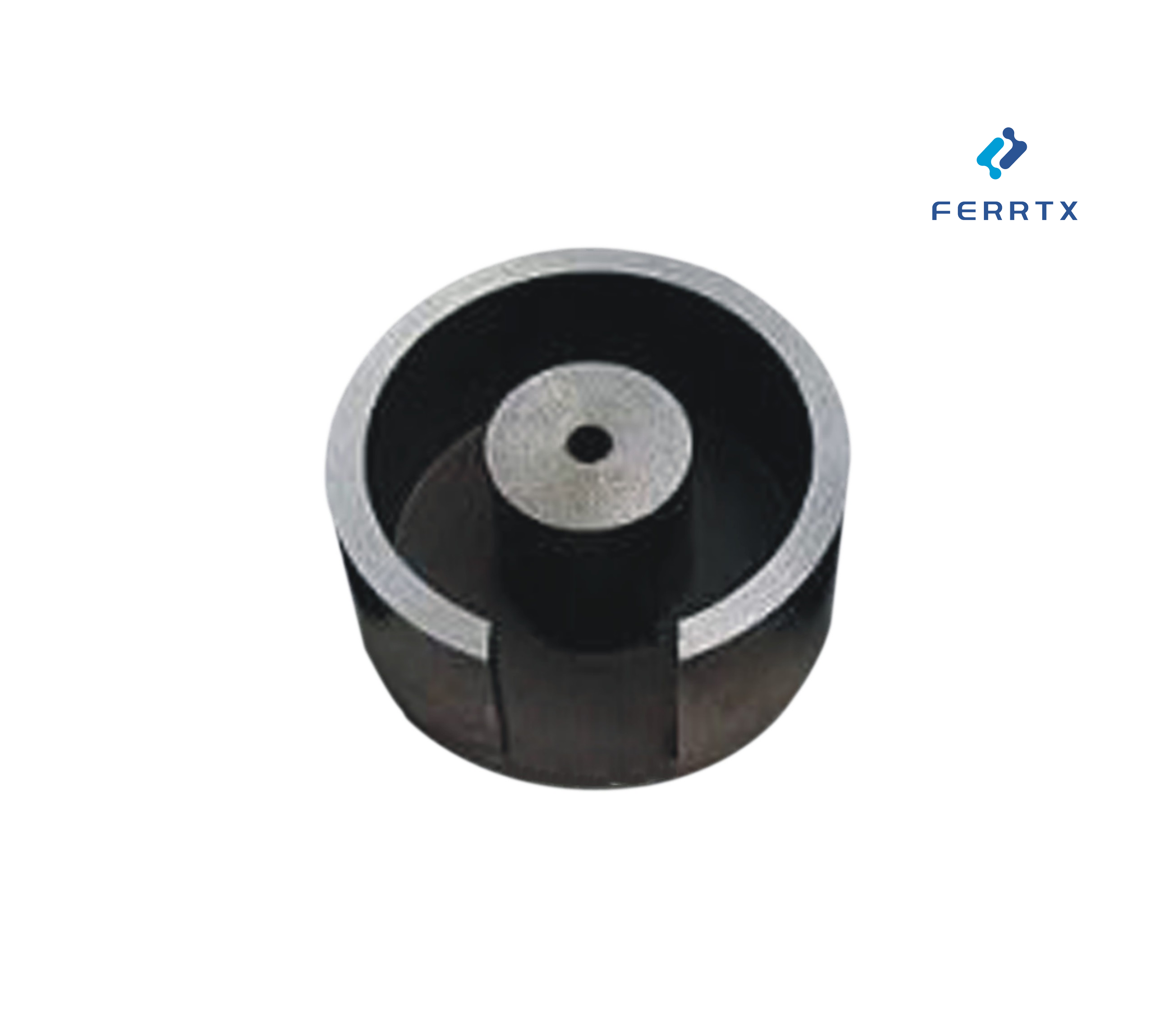

Sendust Cores are soft magnetic powder cores made from an optimized iron–silicon–aluminum (Fe-Si-Al) alloy, widely used in power electronics where high current capability, low core loss, and stable inductance are required.

Compared with traditional ferrite materials, Sendust Powder Cores offer superior DC bias performance, lower audible noise, and excellent thermal stability, making them an ideal solution for high-frequency and high-current magnetic designs.

FERRTX provides a full range of Sendust Powder Magnetic Cores designed for modern power conversion systems, supporting both standard designs and customized requirements.

Low Core Loss

Optimized alloy composition minimizes hysteresis and eddy current losses at medium to high frequencies.

Excellent DC Bias Performance

Maintains inductance stability under high DC current conditions, outperforming traditional Ferrite Core solutions.

Distributed Air Gap Structure

Naturally distributed air gap eliminates the need for mechanical gapping, improving consistency and reliability.

Low Acoustic Noise

Ideal for noise-sensitive applications such as power supplies and industrial control systems.

High Thermal Stability

Stable magnetic characteristics across a wide operating temperature range.

Wide Frequency Range

Suitable for switching frequencies from tens of kHz up to several hundred kHz.

Sendust material is composed of approximately 85% iron, 9% silicon, and 6% aluminum, offering a balanced combination of magnetic permeability and saturation flux density.

Compared with other Magnetic Cores materials such as ferrite or amorphous alloys, Sendust provides:

Higher saturation current capability

Lower sensitivity to temperature variation

Improved performance in power inductors and energy storage components

Sendust Cores are widely used in:

Power Inductors for DC-DC converters

PFC (Power Factor Correction) inductors

Switching power supplies (SMPS)

Solar inverters and energy storage systems

EV onboard chargers and power modules

Industrial power converters and motor drives

In many designs, Sendust Cores are selected as an alternative to Ferrite Core solutions when higher DC bias and lower audible noise are required.

Sendust Powder Cores are commonly paired with various inductor structures, including:

toroidal choke designs for compact, low-leakage applications

High-current Flat Wire Inductor constructions to reduce copper loss

Shielded and unshielded power inductors for EMI-sensitive systems

This flexibility allows engineers to optimize electrical performance while meeting size and efficiency requirements.

FERRTX controls the complete production process of Sendust Powder Cores, including:

Powder formulation and insulation coating

Precision pressing and curing

Dimensional and magnetic parameter inspection

Consistency verification for batch production

All products comply with RoHS requirements and are suitable for global industrial and commercial markets.

We support customized Sendust Core solutions, including:

Core dimensions and shapes

Permeability grades

Loss optimization for specific frequency ranges

Matching with specific winding or Transformer and inductor designs

Our engineering team works closely with customers to ensure optimal magnetic performance for each application.

Stable supply for mass production

Engineering support for magnetic design optimization

Consistent quality for industrial-grade applications

Competitive pricing for global B2B customers

Whether you are designing high-efficiency power converters or advanced energy systems, FERRTX Sendust Powder Cores deliver reliable performance and long-term stability.

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.