Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Product Categories

For electronic component manufacturers and system designers, understanding how these sensing technologies work — and what hardware they rely on — is essential for building next-generation products.

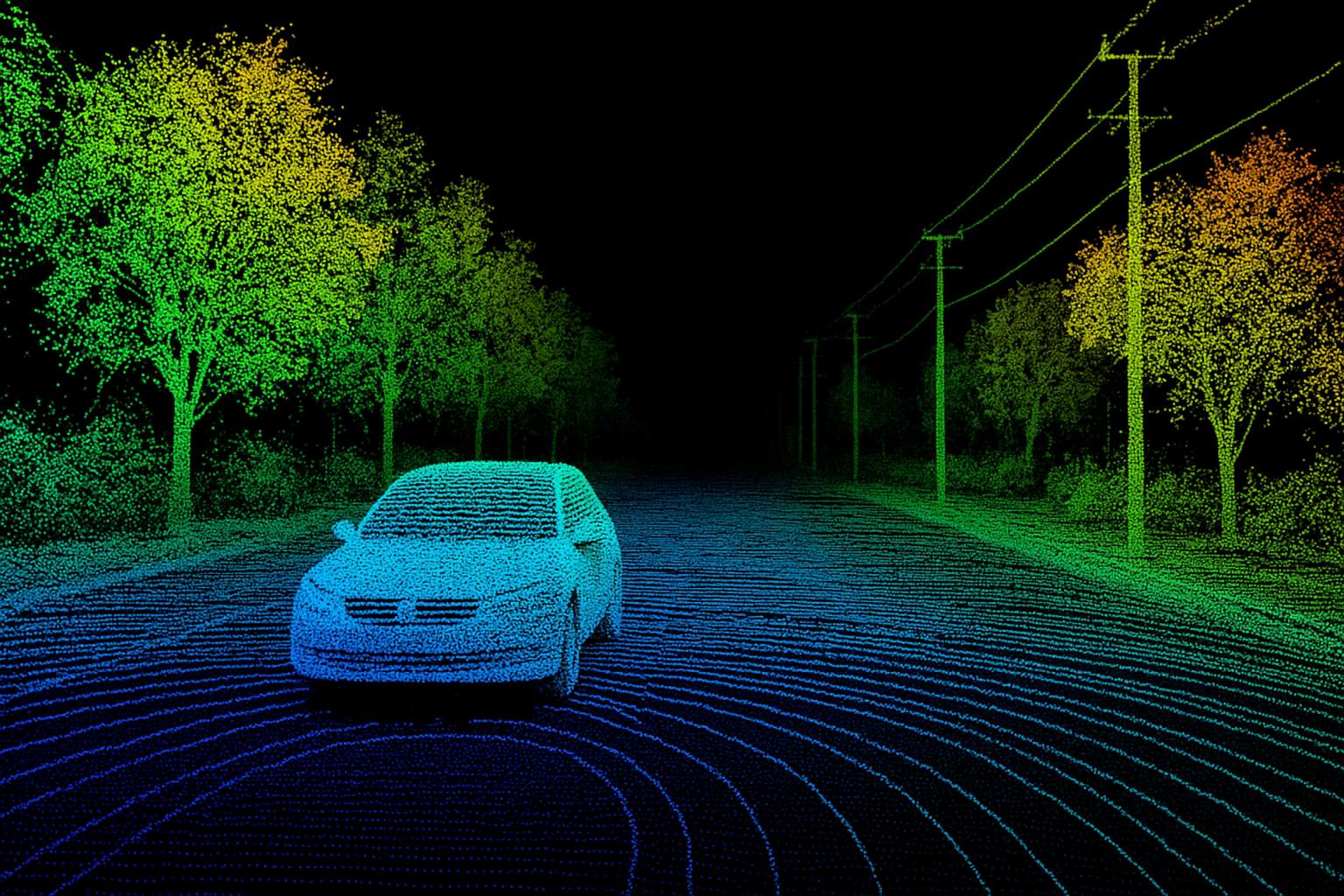

LiDAR uses laser pulses to capture detailed 3D environmental data.

Its exceptional precision makes it ideal for applications requiring high-resolution spatial awareness:

Autonomous vehicles and smart transportation

Warehouse automation and robotic navigation

Smart cities and traffic monitoring

Environmental and infrastructure scanning

LiDAR systems demand reliable power conditioning, magnetic components, noise-suppression chokes and high-frequency circuits to ensure stable performance.

LiDAR uses laser pulses to capture detailed 3D environmental data.

Its exceptional precision makes it ideal for applications requiring high-resolution spatial awareness:

Autonomous vehicles and smart transportation

Warehouse automation and robotic navigation

Smart cities and traffic monitoring

Environmental and infrastructure scanning

LiDAR systems demand reliable power conditioning, magnetic components, noise-suppression chokes and high-frequency circuits to ensure stable performance.

Machine vision systems use cameras and advanced algorithms to interpret images in real time.

Combined with AI and edge computing, machine vision enables:

Industrial inspection and quality control

Robotic guidance in assembly lines

Safety and object recognition systems

Smart manufacturing and IoT automation

High-performance cameras and processors depend on robust power modules, isolation Transformers, EMI noise filters and stable DC supplies — all critical to ensuring low noise and accurate imaging.

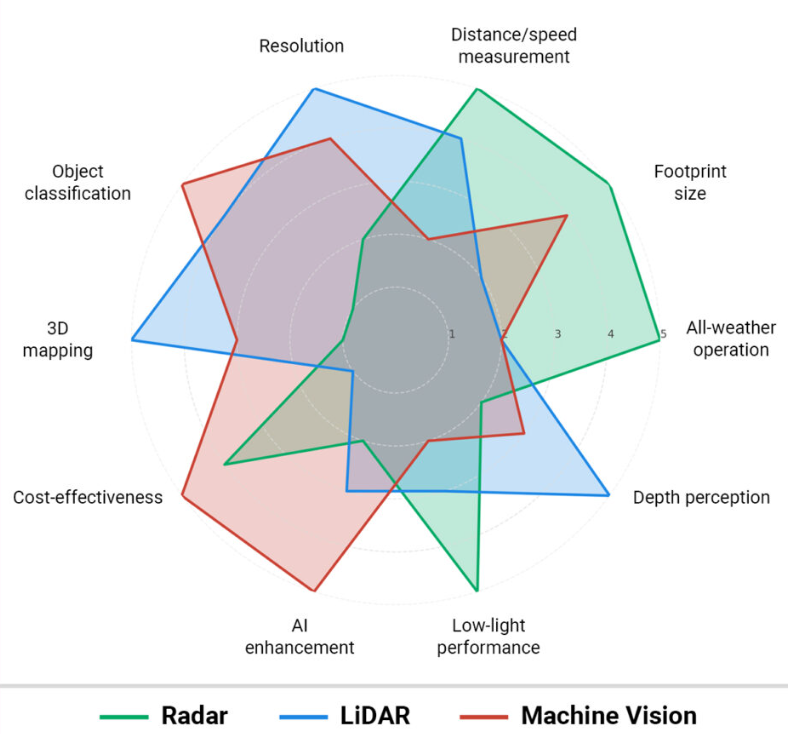

Although radar, LiDAR and machine vision differ in sensing principles, they share common hardware requirements:

Stable and clean power delivery

Low-noise magnetic components

High-frequency chokes and transformers

EMI/EMC suppression for signal accuracy

Customized solutions for harsh environments

As a global supplier of magnetic components, FerrTx supports sensing system manufacturers with:

Precision current transformers

High-frequency inductors

Low-loss chokes

Custom magnetic assemblies

UL94-V0-certified insulation materials

Wide-range operating temperatures

These components help designers build more reliable, durable and accurate sensing systems across automotive, industrial and smart-city applications.

Radar, LiDAR and machine vision are reshaping how machines perceive their surroundings. As demand for intelligent systems continues to grow, the role of high-quality magnetic components becomes even more crucial. At FerrTx, we provide the essential building blocks that ensure stable power, clean signals and long-term reliability — supporting innovation in every advanced sensing application.

Let's get in touch.

About Us

Related Products List

Contact Us

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.