Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: FERRTX

Supply Type: Original Manufacturer

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 2~8weeks

Certificate: ISO/UL/CE/IATF16949/CNAS

Port: Xi'an,Shanghai

Payment Type: L/C,T/T

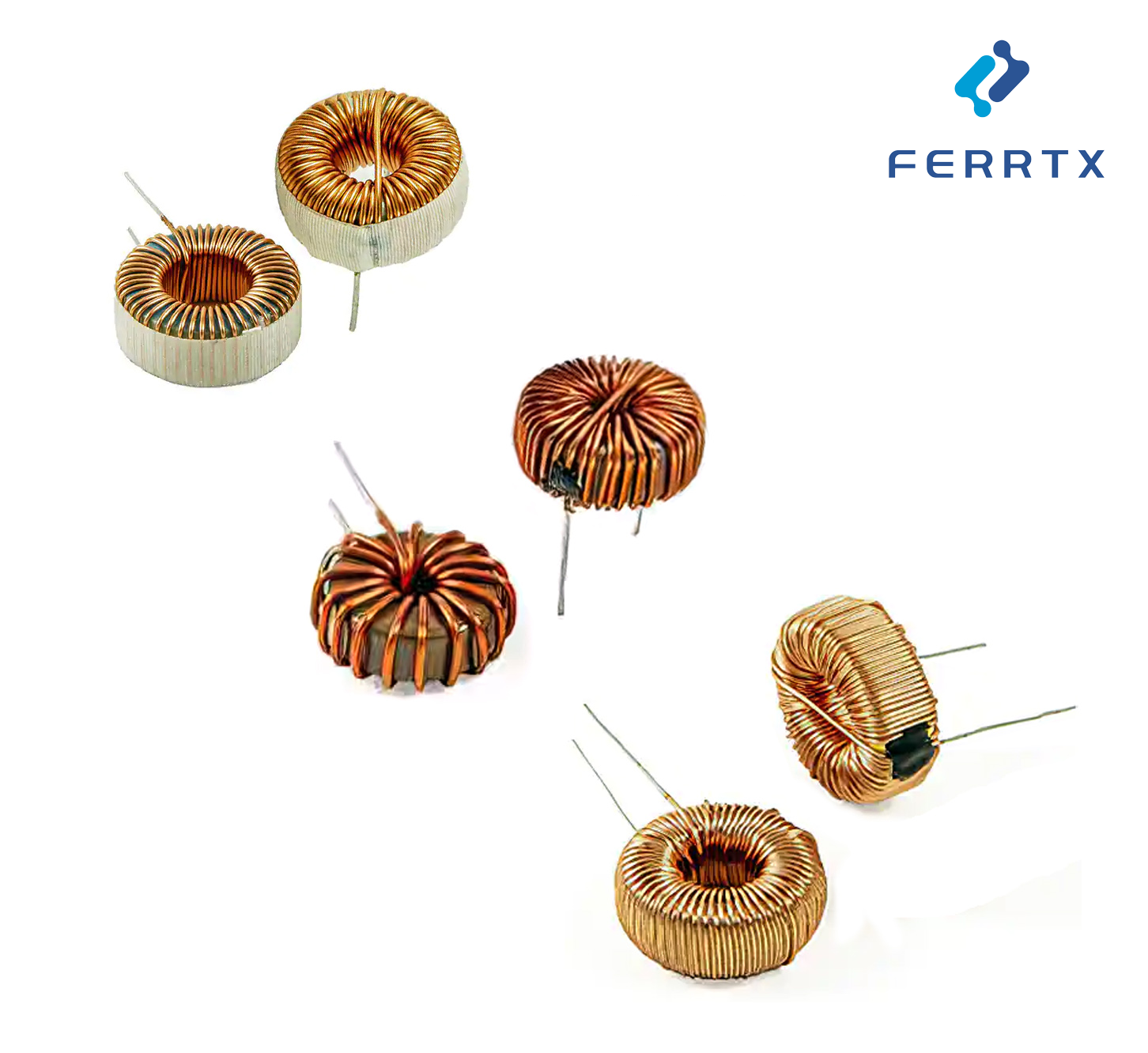

FERRTX provides advanced toroidal choke coil solutions engineered for reliable energy storage, noise filtering, and electromagnetic interference (EMI) suppression in modern power electronics. Our toroidal chokes are built on optimized Magnetic Cores with uniform winding distribution, enabling high inductance stability, reduced leakage flux, and excellent performance across AC/DC converter systems.

With the help of a toroidal choke calculator, engineers can precisely select inductance values, current ratings, and core sizes to achieve optimal circuit performance in compact, high-density layouts.

The closed magnetic loop structure ensures minimal flux leakage, allowing the toroidal choke to deliver stable inductance over wide operating currents.

Low Electromagnetic NoisePerfect for EMI and RFI suppression, especially when configured as a toroidal common mode choke.

High Current CapabilityOptimized copper windings and thermally efficient core materials provide excellent saturation characteristics under heavy load.

Compact, Space-Saving DesignToroidal geometry reduces coil footprint while improving energy density in switching power supplies.

Customizable DesignFERRTX supports fully customized toroidal choke coils including:

Inductance value

Wire type & gauge

Core material (ferrite, iron powder, nanocrystalline, etc.)

Coating, insulation, and mounting options

AC/DC power supplies

DC/DC converters

Power factor correction circuits

UPS and industrial power modules

Toroidal Common Mode Choke units for noise filtering

Differential mode chokes

Line filters for consumer and industrial devices

Router and modem power circuits

Base station power modules

Smart home devices

On-board chargers

EV power converters

Renewable energy systems

We offer a wide portfolio of toroidal choke coils, including:

Common mode toroidal choke

Differential mode power choke

High-current toroidal inductors

Powder-core toroidal reactors

Custom toroidal coils for OEM applications

Each coil is designed to achieve high inductance accuracy and low temperature rise, ensuring long-term operational reliability.

Proven expertise in toroidal inductive components

High-quality core materials for low loss and high current capability

Fast sampling and flexible customization

Stable global production capacity

Reliable performance for industrial, consumer, and communication electronics

FERRTX continues to develop innovative toroidal choke products to meet the evolving needs of modern power and EMI filters.

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.