Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: FERRTX

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 2~8weeks

Certificate: RoHS/ISO/UL/CE/IATF16949/CNAS

Port: Xi'an,Shanghai

Payment Type: L/C,T/T

Our Amorphous Cut Cores are engineered to deliver excellent magnetic performance with extremely low losses, making them ideal for modern power electronics and precision control systems. Compared with traditional silicon-steel or ferrite materials, amorphous cores offer significant advantages in energy efficiency, temperature stability, and saturation characteristics. If you are searching for a reliable supplier with stable quality and competitive Amorphous Cut Core Price, our solutions can fit a wide range of industrial and commercial applications.

Amorphous metal features a randomly arranged atomic structure, allowing it to achieve much lower hysteresis and eddy-current losses than crystalline materials. This results in lower heat generation and higher power efficiency, especially in high-frequency or high-flux environments.

Our cores maintain strong performance even under high-current working conditions. This makes them suitable for magnetic amplifier (mag-amp) circuits, PFC stages, inverter control, and current-regulated systems where stable inductance is essential.

Amorphous alloys maintain magnetic performance over a wide operating temperature range, minimizing drift and improving overall system reliability. This is particularly valuable in continuous-operation power supplies and demanding industrial environments.

Amorphous Cut Cores are widely used in:

Mag-amp circuits for SMPS

Precision power converters

Renewable energy equipment

High-frequency Transformers

AC-DC and DC-DC converter modules

Automotive power systems

If you work with specialized magnetic structures such as toroidal choke designs or advanced High Voltage Inductor assemblies, amorphous material offers better efficiency and thermal behavior than traditional ferrite.

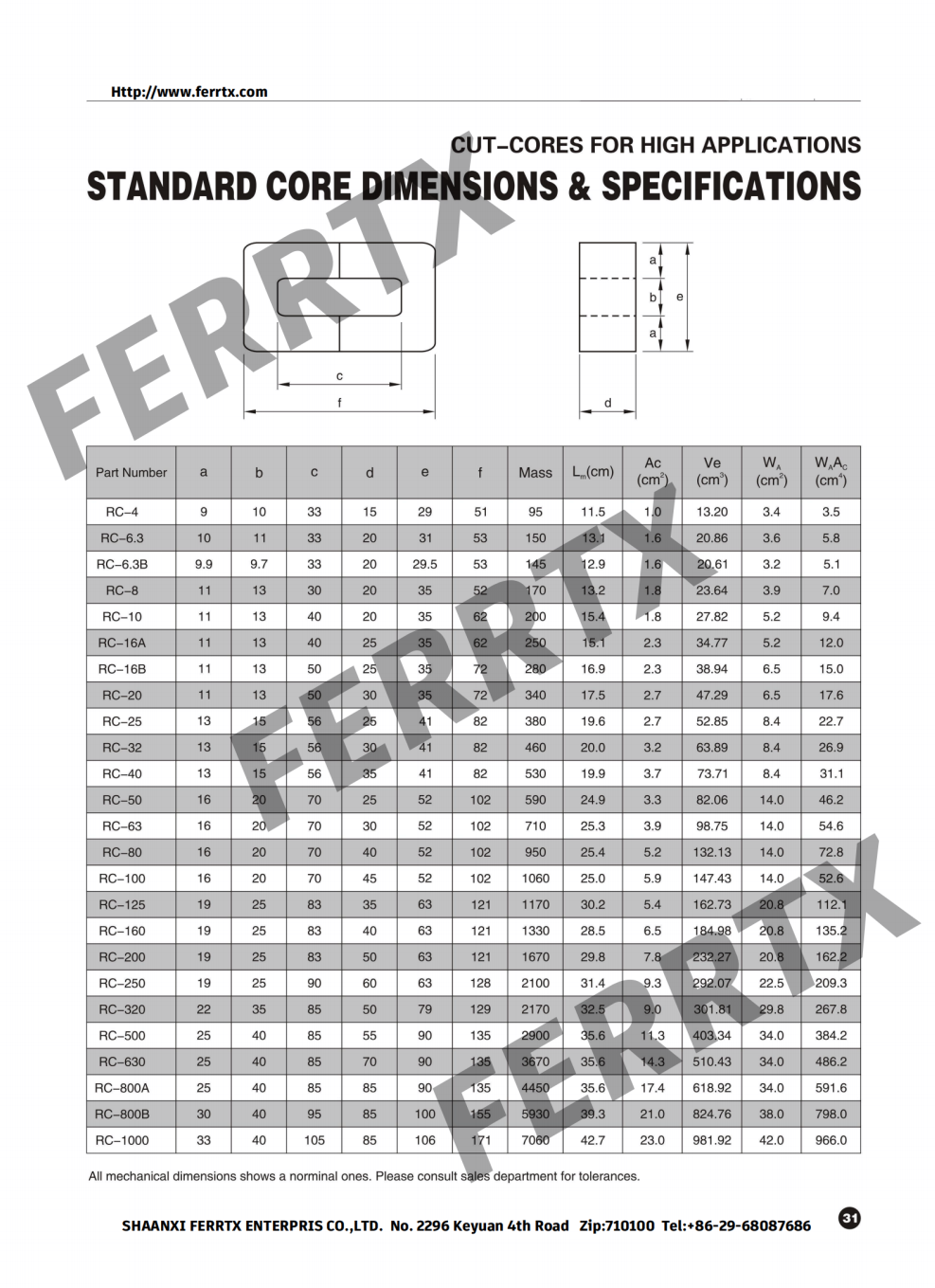

We offer a full range of sizes, core shapes, and coatings, allowing engineers to select the most suitable magnetic characteristics. For OEM/ODM requirements, our engineering team can customize:

Core dimensions

Air gap specifications

Magnetic properties

Coil integration (paired with molded inductors or Transformer winding structures)

Whether you need standard models or customized amorphous cores, our production lines ensure consistent quality and reliable performance.

Low coercive force and minimal core loss

High permeability and stable inductance

Excellent frequency response

Low audible noise and low heat generation

Optional epoxy coating, insulation, or encapsulation

Suitable for compact and high-efficiency power design

Telecom power systems

High-frequency switching power supply

DC-DC/AC-DC conversion

Mag-amp regulators

Inverters and UPS

Industrial automation equipment

Smart meters and power management systems

With years of production experience in magnetic components, we ensure every Amorphous Cut Core meets strict quality standards. From stable material sourcing to automated cutting and annealing processes, every step is controlled to guarantee consistency and performance.

If you need the latest Amorphous Cut Core Price, customized engineering support, or samples for evaluation, our team is ready to assist.

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.