Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

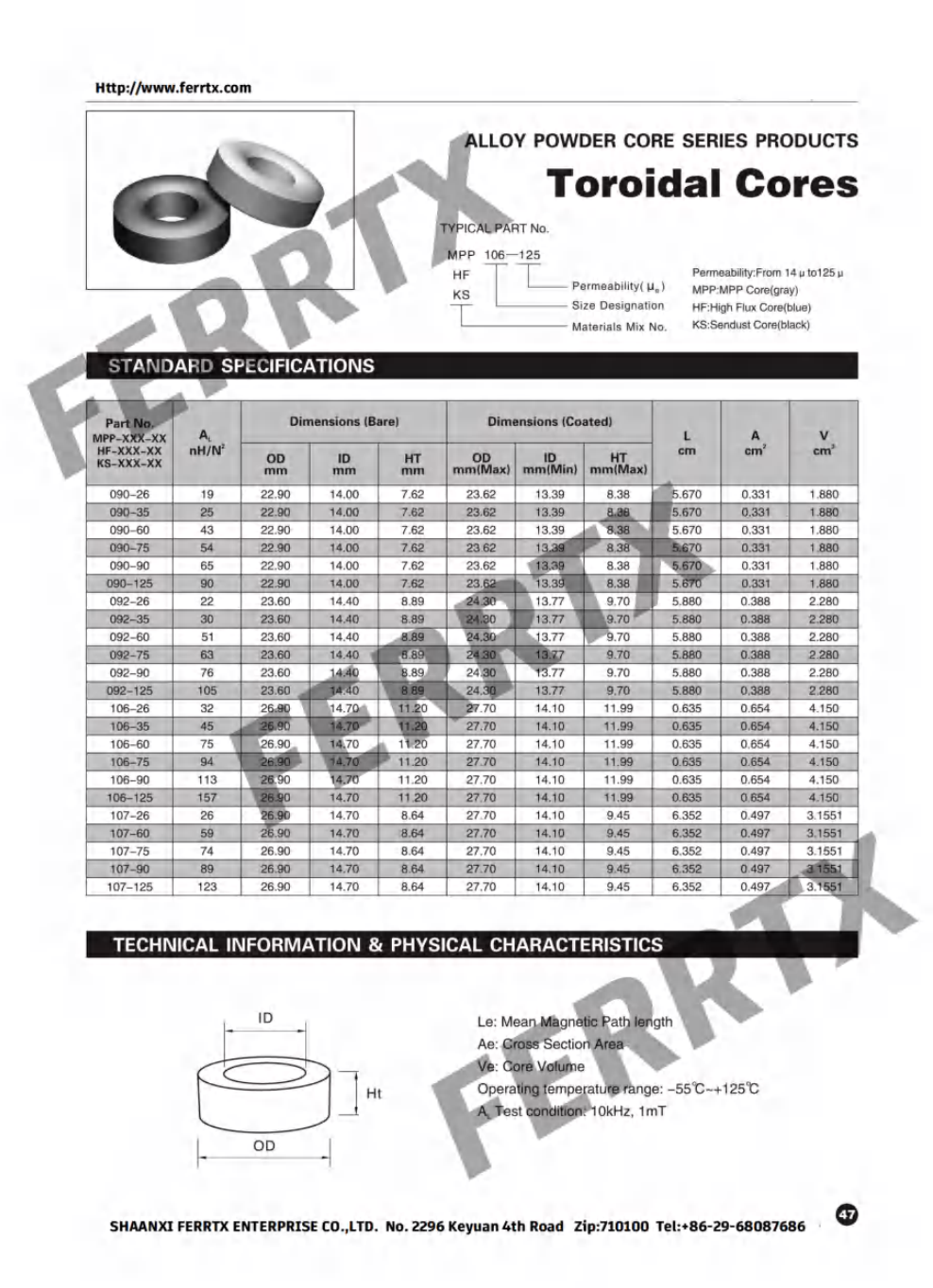

Model No.: High Flux Cores

Brand: FERRTX

Species: Soft

Shape: Pot / Cup Shape

Processing Service: Cutting, Moulding

Permeability Range: 14μ - 125μ

DC Bias Stability: >86%@50 Oe

Operating Temperature: -55°C ~ +125°C

Core Loss (10kHz): <300 mW/cm³

Ve (Volume): 0.11 - 45.3 cm³

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 2~8weeks

Certificate: RoHS/ISO/UL/CE/IATF 16949/CNAS

Port: Xi'an,Shanghai

High flux cores revolutionize magnetic material performance with patented alloy composition, delivering unmatched stability where conventional solutions fail. Unlike standard ferrite cores that degrade rapidly above 30 Oe, our powder alloy technology provides:

Designer Insight: When developing compact Power Inductors for EV fast-charging systems, the 90% permeability retention at 50 Oe enables 22% smaller form factors versus alternatives.

Comparative permeability retention at 50 Oe (per page 2 measurements):

| Material | Initial μ | μ at 50 Oe | Drop |

| High Flux 60μ | 100% | 86% | 14% |

| MPP 60μ | 100% | 67% | 33% |

| Sendust 60μ | 100% | 72% | 28% |

Maintains >80% initial permeability at 100kHz (page 4 frequency curves), enabling applications such as:

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.